- +7 (343) 286-65-31

- Russia, Ekaterinburg, 31 Lunacharskogo str.

- office@npoelectro.pro

HYDRO GENERATOR

Specialists of SPA ELECTROMASH LLC carry out designing, manufacturing, and repair, complex reconstruction, and modernization, supervision of parts and units of vertical and horizontal hydro generator.

- The cost and timing of the work are calculated based on the application.

EXPERIENCE IN SUPPLYING PARTS AND ASSEMBLIES

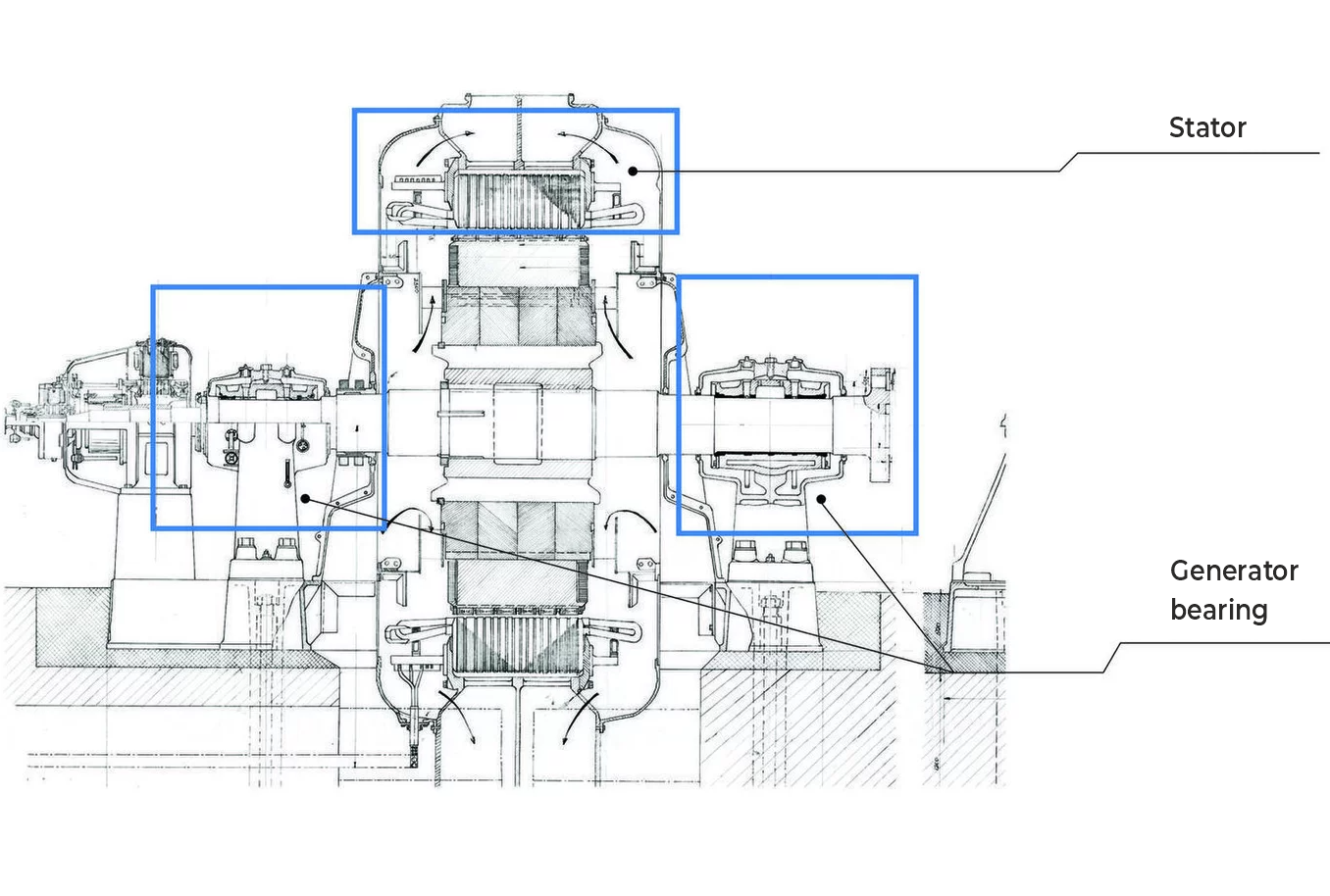

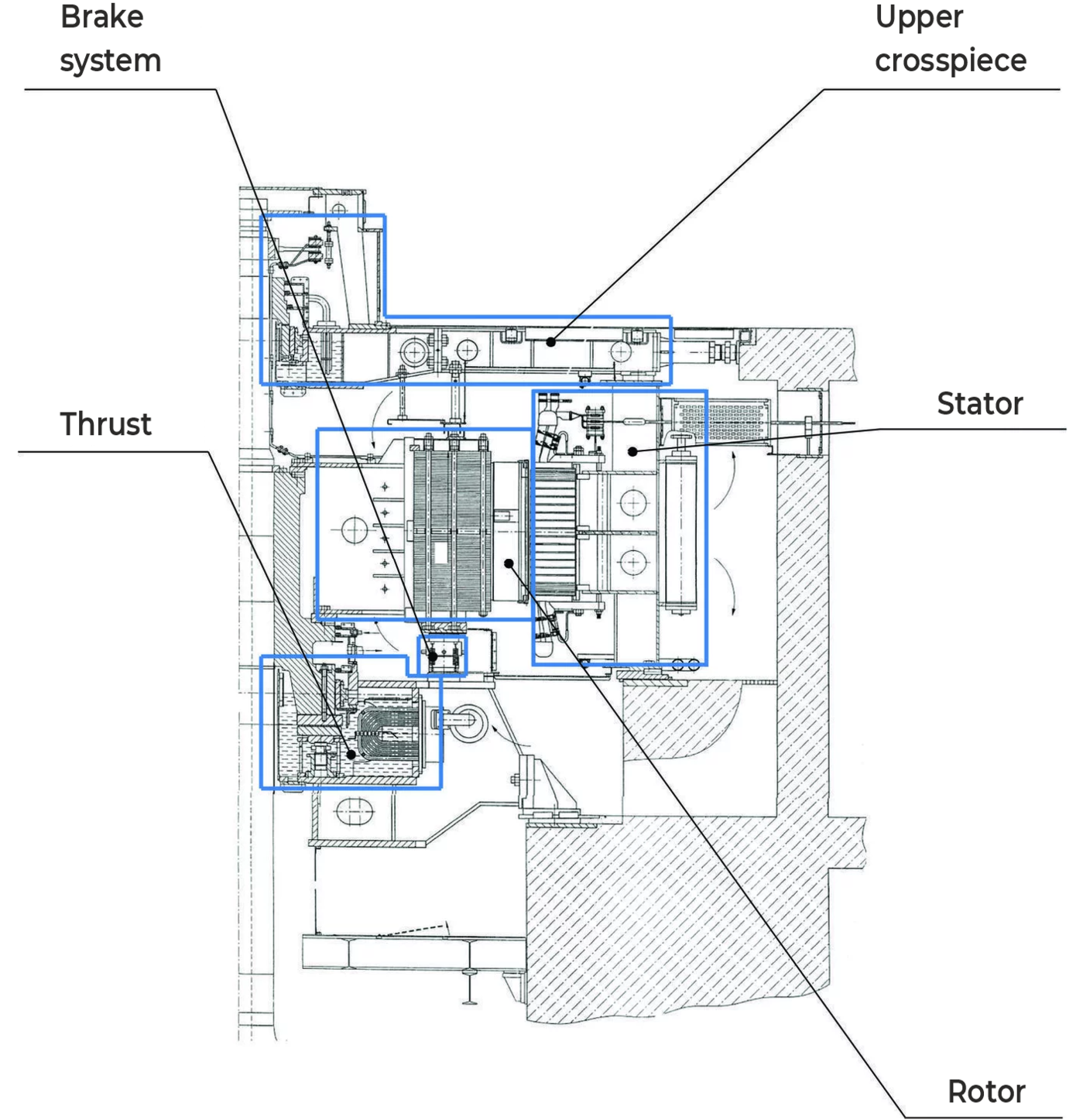

VERTICAL HYDRO GENERATOR

Thrust

- intermediate bearing

- sleeve (rigid support)

- corrugation (hydraulic support)

- category 1 fasteners

Stator

- stator iron

- bandage rings

- stator segment

Rotor

- rotor pole

- pole core

- insulating washer

- sub-pole spring

- fasteners

HORIZONTAL HYDRO GENERATOR

RENOVATION AND MODERNIZATION

The scope of hydro generator reconstruction includes replacement of obsolete active parts, namely:

- core of the stator of large electric machines with the assembly of active steel in a ring;

- stator winding (replacing the insulation, allowing to increase the capacity of the hydrogenerator by up to 10%);

- poles of the main generator rotor.

Modernization and reconstruction of the mechanical part of the generator:

- cooling system of stator and bearing units, namely: oil coolers (replacement of copper pipes with cupronickel ones), air coolers (using finned tube, which allows increasing the cooling surface area);

- generator bearings (replacement of babbitt coating with fluoroplastic one, allowing to reduce wear of working surface and heating temperature);

- of the thrust (conversion from hydraulic support to rigid support, this eliminates the use of the hydraulic system and leaks in the chamber of the thrust);

- replacement of the metal coating of the thrust bearing segments with metal-fluoroplastic coating.