The shipment of manufactured spare parts for the repair of hydrogenerator equipment took place: insulating studs and crackers of guide bearing segments.

Shipment of insulation washers

Insulating washers (upper and lower) poles of the hydrogenator rotor were manufactured and shipped.

Shipment of shearing fingers

The shipment of the manufactured shear fingers of the hydraulic turbine guide device took place.

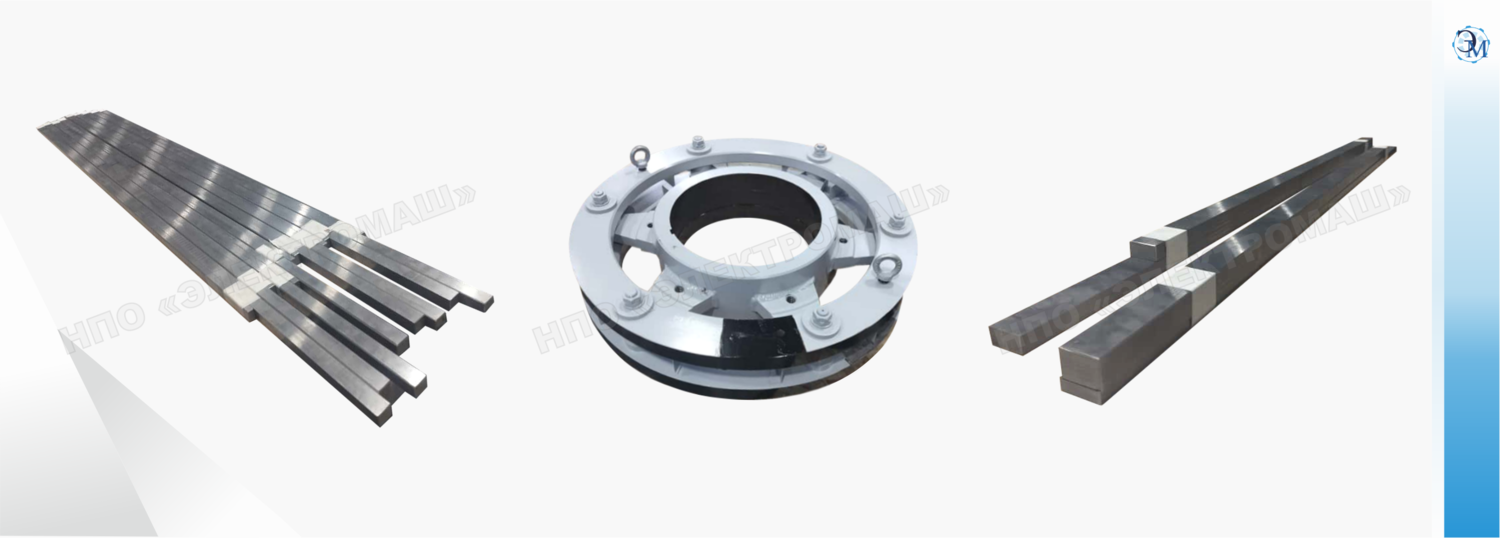

Shipment of spare parts for repair of hydro generator and hydro turbine equipment

Spare parts for the repair of hydrogenerator and hydro turbine equipment were manufactured and shipped: grooved stator wedges, bottom bolts and nuts M140x4 for mating the shafts of the hydrogenator with the turbine, housing insulation of the rotor pole, insulating boxes of the guide bearing segments.

HAPPY NEW YEAR 2026 AND MERRY CHRISTMAS!

We sincerely wish you a Happy New Year 2026 and Merry Christmas!

Be healthy, loved and happy!

Shipment of the rotor pole

The rotor pole of the hydrogenator was manufactured and shipped to replenish the emergency reserve.

Shipment of M20 hairpins

The shipment of the manufactured M20 pins for the overhaul of the hydro turbine took place.

Shipment of insulation washers

Insulating washers were manufactured and shipped for mounting a disk with a hydrogenator support sleeve.

Shipment of hydrogenator support and insulation bolts

The manufactured support bolts of the generator bearing were shipped (to replenish the emergency reserve), as well as the insulating bolts securing the sleeve with the hydraulic spring disc.

Shipment of parts and assemblies for replenishment of emergency stock

The manufactured parts and assemblies of the hydrogenator were shipped to replenish the emergency reserve, such as: pole wedges, contact rings and rim wedges.

Shipment of parts to replenish emergency stock

An emergency reserve for hydrogenerator equipment was manufactured and shipped, namely: electric brushes for contact rings and five types of groove stator wedges.

Shipment of pneumatic valves

The shipment of manufactured pneumatic valves designed to stabilize the air pressure in the hydraulic unit system took place.

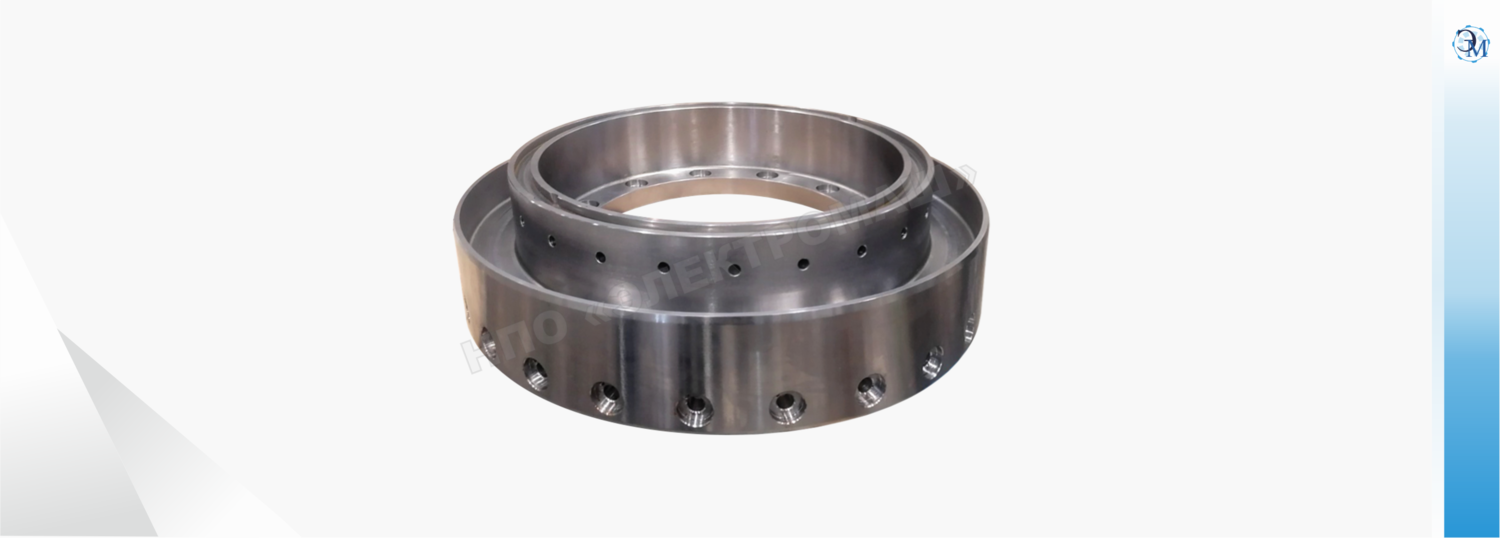

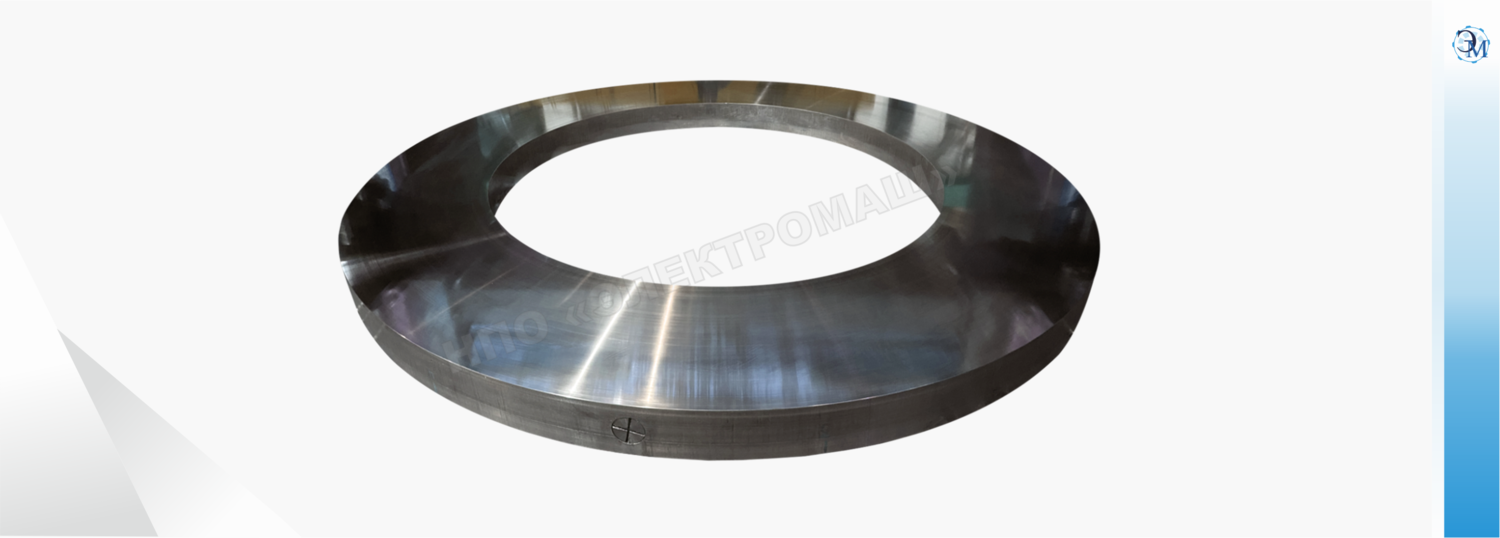

Repair of the podpyatnik disk

The support plate disc with a diameter of 3760 mm was repaired, including: replacement of the insulating layer, restoration of geometric parameters in flatness, roughness, and parallelism.

Shipment of parts to replenish emergency stock

Parts were manufactured and shipped to replenish the emergency reserve, namely: the main spool of the hydraulic turbine spool block and two types of support bolts for hydraulic generators.